The industry standard is to use 1 2 inch thick backer board on wall tile installations such as a tub surround.

How many studs and screws for wall durock and tile.

It s available in sheets of many sizes with 3 foot by 5 foot sheets being the most common.

The durock spec sheet indicates you use cgc usg tilebacker screws or equivalent.

Whenever you re laying tile on a wood subfloor you need to first install cement backerboard to prevent leaks and water damage.

For steel stud applications use 1 1 4 durockbrand steel screws leave a 1 8 gap between all panel edges.

Cement board commonly sold under trade names such as durock hardiebacker and wonderboard is now the standard underlayment used for ceramic porcelain or stone tile laid with thinset mortar adhesive cement board is used for most floor tile and has all but replaced plywood and drywall backer materials for wall tile applications in wet areas like showers and tub surrounds.

The second problem is that the last stud on one end goes behind the other wall and i can t attach the durock to it as there s no way to screw it in.

Do not countersink screws.

We use cookies to provide a personalized site experience.

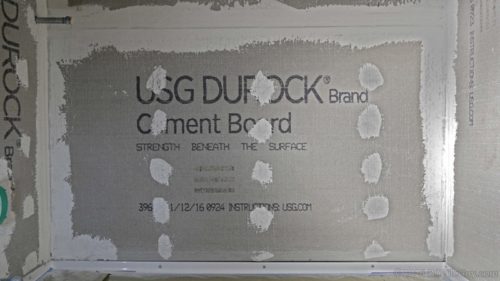

Usg durock brand tile backer screws.

After i realized i was creating a problem i stopped tearing out the wood lath in this area.

You really do not need that feature for your application.

Cement backer board comes in two standard thicknesses 1 2 inch and 1 4 inch.

Install screws with screw heads flush with the panel surface.

Durock brand tile backer screws are high quality corrosion resistant fasteners designed for attaching multiple types of backerboards and underlayments to wood or steel framing inside and out.

Drilling thread design for 14 to 20 gauge metal stud thicknesses.

Cement backerboard is a thin layer of concrete with fiberglass mesh on both sides.

Waterproofing if waterproofing is desired use usg durock tile membrane or usg durock.

Maximum allowable deflection based on stud properties only l 360.

Screw spacing is 8 o c.

Substrate for tile in shower or outside.

Just enough room to slide it in there.

They are corrosion resistant because durock is used alot in wet areas ex.

Fasten board to wood studs spaced at 16 o c with 1 1 2 hot dipped galvanized roofing nails spaced 8 o c for walls 6 o c for ceilings or using 1 1 4 durockbrandwood screws with the same spacing.